The Tin Plate Industry of Cwmbran

Iron - Strong material but rusts easily.

Tin - Low melting point, non toxic, rust resistant, cheap to produce and lightweight.

.. By coating iron/steel with tin the benefits are clear ..

Have You heard of the Conway Family?

In 1802 George Conway brought his family to Cwmbran and set up his Tin Plate works at Pontnewydd, formerly known as the Pontnewydd Iron works.

In 1806 John, George's oldest son opened another Tin Plate factory, known as the Edlogan Works at the bottom of Chapel Lane, Pontrhydyrun.

The Conway's family home known as Pontrhydyrun House was situated next to the Edlogan works.

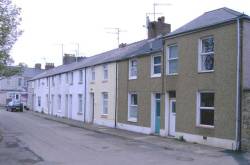

They had homes built for their workers, one street adjacent to the site of the Lower Pontnewydd Works, Conway Terrace, another Conway Close.

The Family founded Pontrhydyrun Baptist Chapel and several family members are buried there, including George who died in 1822.

For more info on Pontrhydyrun Baptist Chapel / Church click here

In the latter part of the 19th Century there were a further two Tin Plate Works in the immediate area, operated by descendants of George and John Conway.

Lower Pontnewydd Works - Edlogan Works - Tynewydd Works - Avondale Tin Plate Works

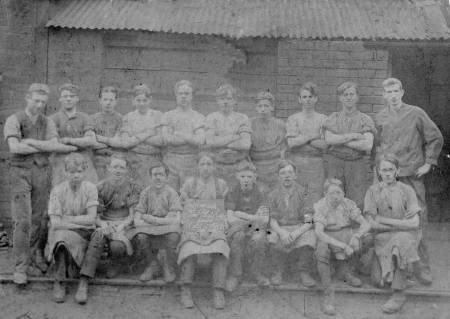

... Avondale Tin Plate workers - circa 1900 ...

... Avondale Tin Plate Company Limited `Cold-Rolls` workers Circa 1947-1950 ...

Photographs, courteously provided by Mrs. Ceinwen Hargrave.

One of the `Rolling Machines` at Avondale Tinplate works

Photograph circa 1935, courteously provided by Norman Nicholas who relates ..

The gentleman at the top of the `Rolling machine` was my grandfather - Bert Nicholas who was born in 1900 - I remember him telling me that they used to go to the Oddfellows Inn in Pontnewydd, have half a gallon "to replace the body fluids after work", go home for tea and then go out in the night for another session.

I also remember visiting the works once when I was off school recovering from chicken pox. I was about 7 years old - circa 1954/55. There was a blacksmith there called Mr. Lippot. I recall, with his help, removing a small red hot billet of steel from the forge using a tongs and then holding it under a steam hammer to beat it into shape, which scared the living daylights out of me. Mr. Lippot went on to carve an ash wood handle and made that billet into a small garden spade (junior version to suit a 7 year old) which I used to help my grandfather in the garden.

Colin Bowen, formerly of chapel Street - Pontnewydd relates:-

I worked in Avondale tinplate for a few years before I left to work on the railways. I remember the hot rolling mills at Avondale very well.The two gentleman in the photograph above are doing a very specialised job it is called `dressing the rolls`; after the mills had run for a week the rolls would pick up scale and pits in the surface of the rolls so they had to dress the rolls which would involve putting a `jig` on the mill; then they would fix a small grind stone to the jig and then they could run it back and fore the rolls as you can see in the photograph, the top roll is finished, it has a nice shine and the bottom roll, is almost

finished.If they did not get rid of the scale and pits it would mark the tinplate and makethe tinplate unsaleable. Dressing the rolls would normally take place on a Sunday when the factory was empty. The time I worked at Avondale, around 1948 the manager was Mr. Allan Jones, he bought himself a new car called an Austin Atlantic .... wow !! this was some car in those days, back in the 1940s.